feature / product-design / designmatters / students / fall-2020

October 07, 2020

By Solvej Schou

Images courtesy of Shield Makers, Andy Lin, Tricia Sada and Hon Li

Shield Makers

Product Design students help create face shields for frontline medical workers

In early March, recent Product Design alumni Tricia Sada (BS 20), Hon Li (BS 20) and James Gildea (BS 20) were all busy students taking courses on the Hillside Campus and getting ready to graduate at the end of the Spring term. Then COVID-19 cases started climbing in the U.S., California went into lockdown, their classes went online and their lives shifted dramatically.

Out of that shift came the need—more than ever—for designers to put their problem-solving skills to immediate use. Sada, Li and Gildea got that chance in late March with Shield Makers, an effort to design and produce face shields for health care personnel at Downey’s Rancho Los Amigos National Rehabilitation Center (RLANRC) and other Los Angeles County Department of Health Services (LADHS) facilities where personal protective equipment (PPE) was in short supply.

Our goal was to protect as many health care workers as possible with the skills we’ve gained from Artcenter.

Hon LiProduct Design recent alumnus

“The project gave me, James and Hon a sense of purpose, to feel like we’re contributing,” says Sada via Zoom from her house in Monrovia. “It distracted us from all the stresses and anxieties going on. It was an opportunity that I could have never expected.”

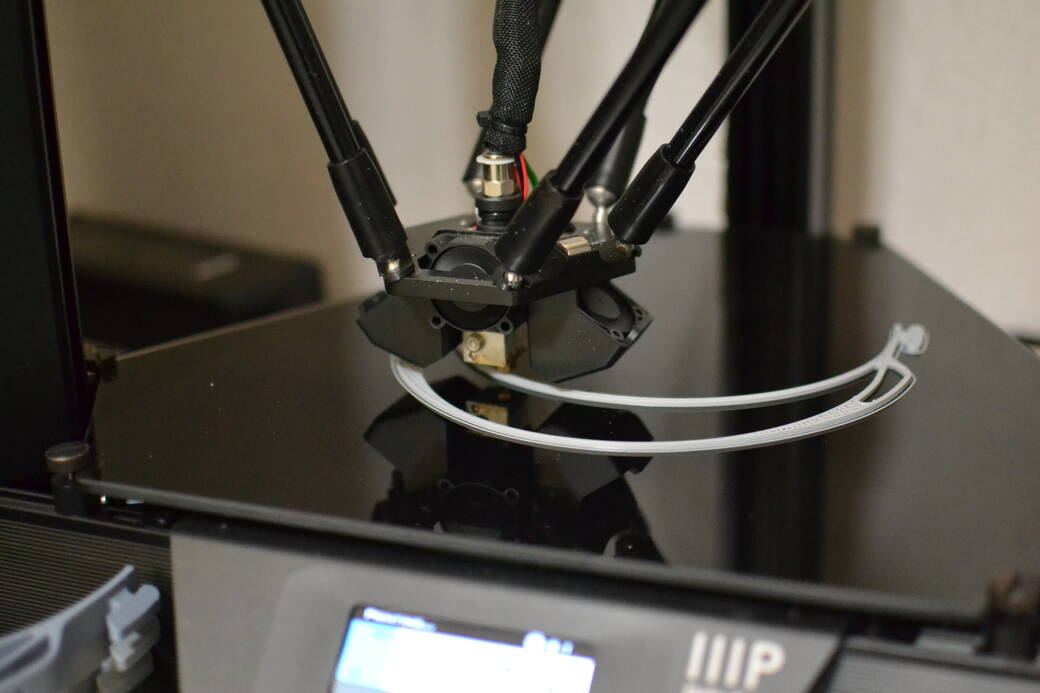

Shield Makers began when engineering and clinical staff at RLANRC started investigating ways to meet the challenge of the dire shortage of PPE. They quickly identified face shields as items that could be used by medical workers during the deadly coronavirus pandemic, and could also be easily made. The hospital’s orthotics staff, led by director Chuck DuBourdieu, produced several hundred shields using materials for making braces. Then DuBourdieu contacted rehabilitation engineer and Product Design Assistant Professor Andy Lin, founder and director of RLANRC’s Rancho Emerging Tech Lab, to look into 3D printing as a quicker method of production. Lin, whose focus is on emerging technologies for individuals with disabilities, reached out to Li, Gildea and Sada as a core leadership team, alongside key staff at the hospital.

From March through June, Li, Gildea and Sada involved more than 30 ArtCenter students and faculty in Shield Makers, producing more than 3,800 face shields—mainly using 3D printers and silicone casting—that were distributed to workers at the hospital, other LADHS facilities, and also non-LADHS facilities, including more than 35 smaller hospitals, assisted living centers and clinics. Mostly RLANRC staff, with continued help from Li, produced the shields after that.

“Hon, James and Tricia’s tireless efforts in the first few months of Shield Makers enabled us to maintain and evolve the design and methods of fabrication, and they laid the groundwork,” says Lin. “They were the ones working on day-to-day tasks related to the project, while maintaining communication with other students, who helped in different ways.”

As a student, Gildea took a 2018 course co-taught by Lin in the College’s social innovation department Designmatters. Lin, who is co-teaching the Fall Product Design course Product Design 3, first met Sada at an early 2020 Caltech event, says Sada, and he later gave her and Li an impactful tour of RLANRC in February. In March, Lin reached out to Li, Gildea and Sada for Shield Makers, they formed a Facebook Messenger group chat to bounce ideas off one another, and everything steamrolled from there.

“We started inviting our friends—other students—to the chat, and it just kept growing and growing,” says Sada, who took on a project manager role and began organizing volunteers. “At that time, I had started to lose my drive, and Shield Makers gave me motivation,” she adds. “I learned about leadership skills, and [also] that I really love working with a lot of people.”

Li, Gildea and Sada—who each already owned a 3D printer at home—began working collaboratively, along with Lin and other clincal staff at RLANRC, to prototype designs. “Hon and James were really the ‘doers,’” Sada says. “They went hard at making the face shields.” They often spent evenings working at the RLANRC’s Rancho Emerging Tech Lab, dedicated to the project, and driving to and from an open warehouse at RLANRC to house 3D printers, says Lin. During prototyping, Gildea delivered shields to doctors at Huntington Hospital and Adventist Health Glendale to get feedback on the team’s designs.

“I hope that we can learn from this pandemic and prioritize innovative designs that will help with crises in the future,” says Gildea. “I’m really grateful for all the people who took the time to help and participate in our research and production. I feel really humbled by how hard health care personnel work. It’s scary how dependent we are on supplies.”

There’s so much opportunity to create something new, to help people. I want to seize that opportunity.

Tricia SadaProduct Design recent alumna

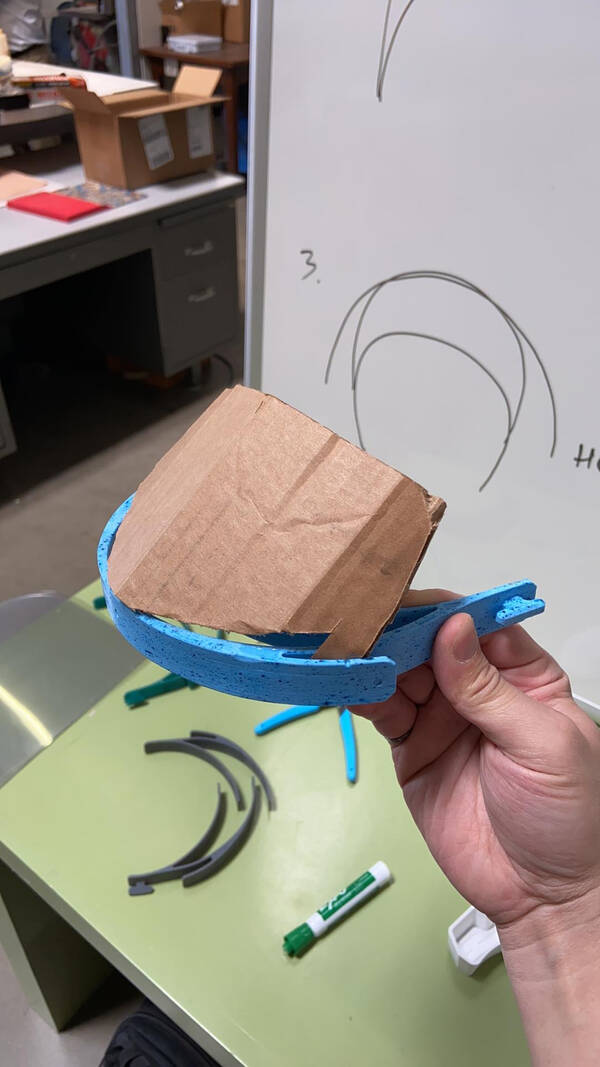

When Li, Gildea, Sada and Lin reached out to faculty members and corporations for help, they connected with Designmatters Executive Director Jennifer May and Regina Dowling-Jones, vice president of ArtCenter’s Strategic Partnerships. More than five local organizations—including the Los Angeles County Library, the design firm SmithGroup and the software company Supplyframe—joined Shield Makers as partners. Electronics retailer Monoprice donated 25 MP10 and seven Delta Pro 3D printers to the project. GreenGate3D donated 3,000 PET thermoplastic sheets and a few spools of PETG filament plastic, made out of recycled plastics. Product Design Chair Chris Hacker donated his own money to buy a vat of silicon molding material, says Sada, for a silicone casting process producing 150 parts per day.

After evaluating and iterating upon existing open source designs for face shields, and testing them for longevity, comfort, cost, sterilization and effectiveness in a clinical setting, Shield Makers publicly released instructions for designs using three modes of production—3D printing, silicone casting and laser cutting—so others can make face shields for their communities. The 3D printed shield includes a headband made out of PLA or PETG filament plastic, a flexible top insert, and a transparent shield. Each face shield takes one to two hours to print. The cast design uses silicone to create molds to cast urethane headbands, which are then attached to the shield using rivets.

“Shield Makers’ success was definitely due to our team’s collaborative nature and our goal to protect as many health care workers as possible with the skills we’ve gained from our years at ArtCenter,” says Li.

Sada, who grew up in both Buffalo, New York and Indonesia, where her family lives, inspired her uncle in Jakarta to fabricate 2,000 face shields using 3D laser cutters and a design she found online for him. He delivered the shields to local hospitals across Indonesia.

Shield Makers also propelled Sada to volunteer at the end of the Spring term and create a website for Open COVID Pledge, an initiative developed by an international group of scientists, entrepreneurs and lawyers calling on organizations to make their patents and copyrights freely available in the fight against COVID-19. “My parents, in Jakarta, are very proud of me for doing that,” she says. Sada tears up a minute later, reflecting on a video they made for her for her Spring graduation, when it shifted from being in person to online due to the pandemic.

After volunteering for Shield Makers and Open COVID Pledge, Sada continued learning through the ArtCenter Honors Term program. She was granted the post-graduation extra ninth term and spent the summer with the Interaction Design Department, boosting her skills. This fall she’s set to start a job in Boston as an industrial designer at Gillette, where she interned in 2018. And she aspires to build her own business, one with lasting social impact. The COVID-19 pandemic has strengthened that goal.

“I want to understand how to design everything, from a service product to an app to software, because solutions come in many forms,” she says. “There’s so much opportunity to create something new, to help people. I want to seize that opportunity.”