feature / alumni / product-design / on-03

October 25, 2024

By Solvej Schou

Images courtesy of Reiten Cheng

In Practice: Reiten Cheng

The alum’s 3D-printed, open-source machine Polyformer recycles clear PET plastic bottles into filaments for 3D printers

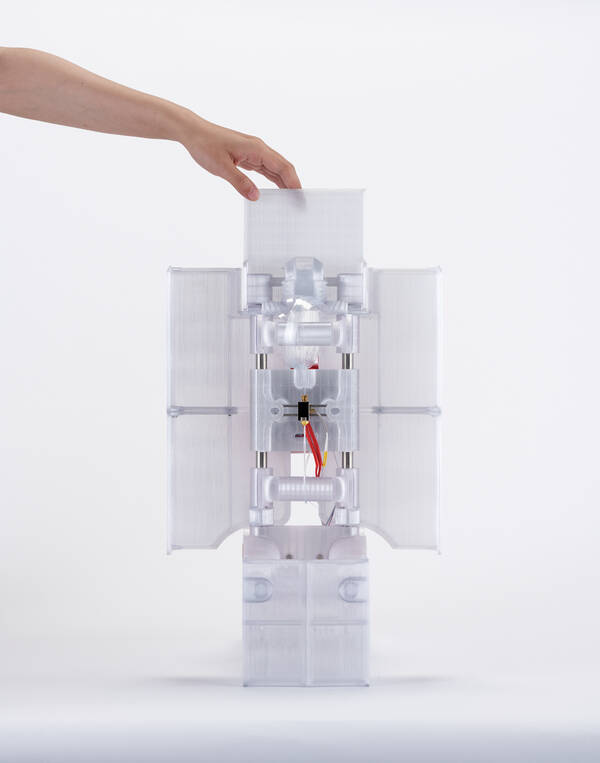

A 3D-printed, open-source machine that recycles clear polyethylene terephthalate (PET) plastic bottles into filaments for 3D printers, Polyformer is the brainchild of Product Design alum Reiten Cheng (BS 22), who created it as an ArtCenter student.

“Entrepreneurship, to me, means having a new idea and acting on it—disrupting the market and challenging the status quo,” Cheng says. “I imagined a plastic bottle recycling machine that everyone in the world could build with accessible parts, that evolves with community effort, and that is elegant and easy to understand.”

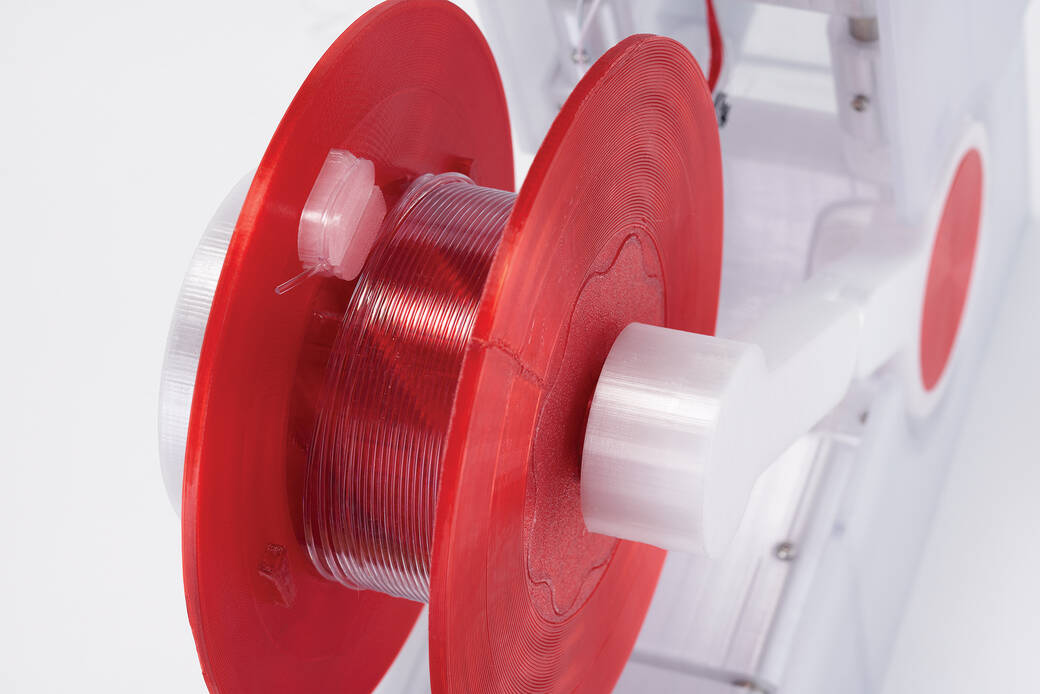

L-shaped and compact, Polyformer uses a slicing tool that cuts a plastic bottle into a long ribbon. The ribbon is then fed into Polyformer’s hot end, where the strip is thermoformed into a 1.75-mm filament. Once cooled, the filament is mounted onto Polyformer’s motorized spool, which can be removed and inserted into any 3D printer.

Polyformer machines have been built by more than 300 people in over 50 countries. In 2023, Cheng won a James Dyson Award, Core77 Design Award and multiple International Design Excellence Awards for his creation.

Raised in Nanchang, China, Cheng built his first electric motor in high school. He moved to the United States in 2016 to study mechanical engineering at Penn State University, then transferred to ArtCenter.

Now based in Seattle, he has been working as an industrial design architect at Meta Reality Labs, designing the next generation of mixed reality headsets. “It feels great to work among the most talented people in the world, pushing the boundaries of technology,” he says.