SABIC

Transportation students journey to the year 2030 to see the future of cars. No time travel machine needed.

Kids who are five years old today might be happy to know that ArtCenter Transportation Design students are already thinking about the future of cars and what they’ll be driving in 2030.

And the designers are drawing inspiration from an unexpected source: the wonderful world of plastics.

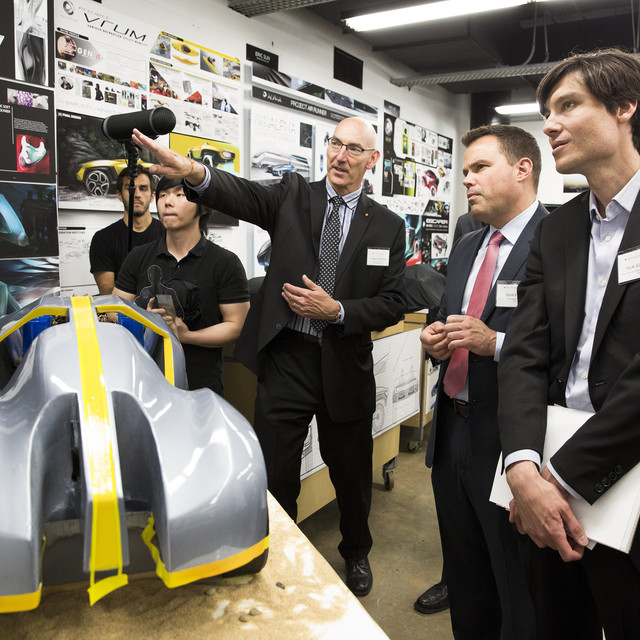

It’s all part of a three-month long design project and competition, called Design for Alpha, sponsored by plastic manufacturer SABIC. The project challenged students to come up with forward-thinking ideas for vehicles that anticipate the future driving needs of anyone born after 2010—dubbed Generation Alpha—and then find ways of using the plastics of today and tomorrow to meet those needs.

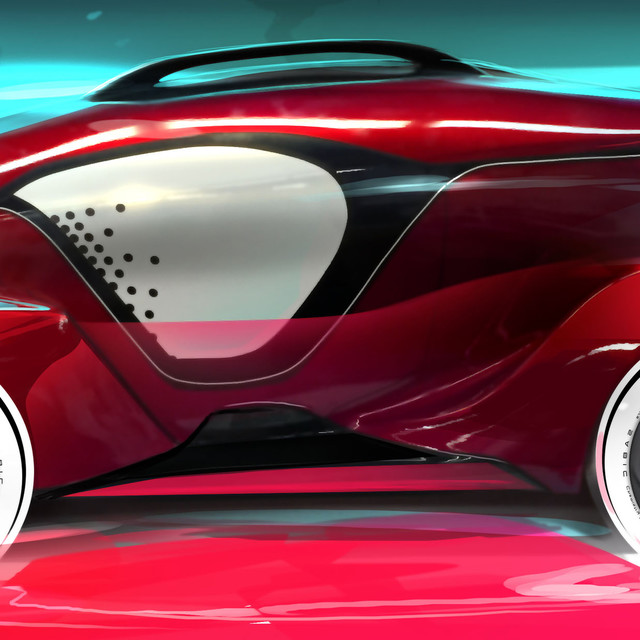

Among the more jaw-dropping outcomes: a car with a single, flexible plastic suspension that replaces the multiple suspension parts used in cars today; a vehicle that encourages both digital and physical social interaction; and an autonomous car that employs thermoplastic technologies and a gas-wind hybrid turbine engine to take the drag out of long commutes.

Transportation Design student John McCarthy, who won the $5,000 first-place scholarship award in the competition, saw the project as an opportunity to address a problem that is expected to increase in the coming years: the tendency of modern technology to turn people into Internet recluses. “The Internet and technology have made it much easier for people to not have to interact physically, but people require real-life human interaction and touch to live healthy and happy lives,” he says. “I also think that managing your online life in the future will become much more difficult because most daily tasks will have to be done online. I wondered if a vehicle could address both of these issues.”

His answer: the Hotspot Urban Base, an autonomous vehicle that merges the digital and physical lives of its three passengers with seating that can be endlessly customized through the use of memory shape polymers; outlets for engaging digital experiences; and seating conducive to conversation.

In other classes you are constrained by the requirement of the materials and manufacturing that are used to create cars now. With 3D printing and plastic polymers, the scope of what can be manufactured is limitless.

John McCarthyTransportation Design student

Second-place winner Eric Sun wanted to design a car that could help address the needs of commuters in increasingly densely populated cities. “As more start-ups crop up and cities expand, Generation Alpha drivers will have to commute greater distances at higher speeds.” His model, the Air Runner, combines autonomous driving, aerodynamic efficiencies and lightweight form for a ride that is fast, comfortable and energy efficient.

For many of the students, designing with plastics and plastics technologies in mind was an eye-opening experience. “In other classes you are constrained by the requirement of the materials and manufacturing that are used to create cars now,” McCarthy explains. “With 3-D printing and plastic polymers, the scope of what can be manufactured is limitless.”

“Before this class I’ve only designed sheet-metal cars,” says Sun. “This project forced me to think about the materials as the essential part of my design, rather than something simply to put paint on.”

“The project really required the students to take a leap of faith,” says ArtCenter Transportation faculty member and project lead Dave O’Connell. “We pushed them to think about how technology could evolve by 2030.”

How does a materials-based class like this one help prepare students for careers in Transportation Design? “What students usually don’t know, and what I hope they learn here, is that it doesn’t matter what you’re designing; you may only be as good as your materials supplier,” answers O’Connell. “Your supplier can be your best friend and partner in the process. Bringing them into the design process early on will open up the possibilities of what can be achieved.”

McCarthy offers a similar lesson learned: “Knowing what materials are out there can really help you design new and innovative things. It can also help you in selling your design solution, because when somebody says, ‘Oh, no, that can’t be built,’ you can say, ‘Oh, yes, it can, and this is what you would use and this is how you would do it.’”